The Refrigeration dryer is the classic dryer in compressed air treatment. Pressure dew points of approx. 2-5°Ctd are achieved with a Refrigeration dryer. It thus protects against line corrosion, product damage and damage to compressed air-operated drives and devices.

The majority of Refrigeration dryers available on the market only measure and monitor the Temperature of the refrigeration unit, but not the actual moisture content of the Compressed air.

However, pure temperature measurement is not sufficient for the following reasons:

- Increased humidity in the intake air (e.g. hot and humid summer) leads to overloading of the Refrigeration dryers. Although the temperature of the refrigeration unit is constant, the entire moisture content of the air cannot condense. Result: The Dew point after the Refrigeration dryer is higher than the temperature measurement indicates.

- Increased compressed air consumption leads to the dryer overrunning. Due to excessive air speed in the dryer, there is no time to cool the compressed air to the specified condensation temperature of 3°C. Result. The Compressed air after the Refrigeration dryer has a higher Dew point and thus residual moisture content than the Temperature specifies.

- Even with an excellently functioning and designed Refrigeration dryer, it can happen that the integrated condensate separator is defective and the condensate produced is not discharged. The already dry Compressed air carries the condensate with it and thus has an increased Dew point again.

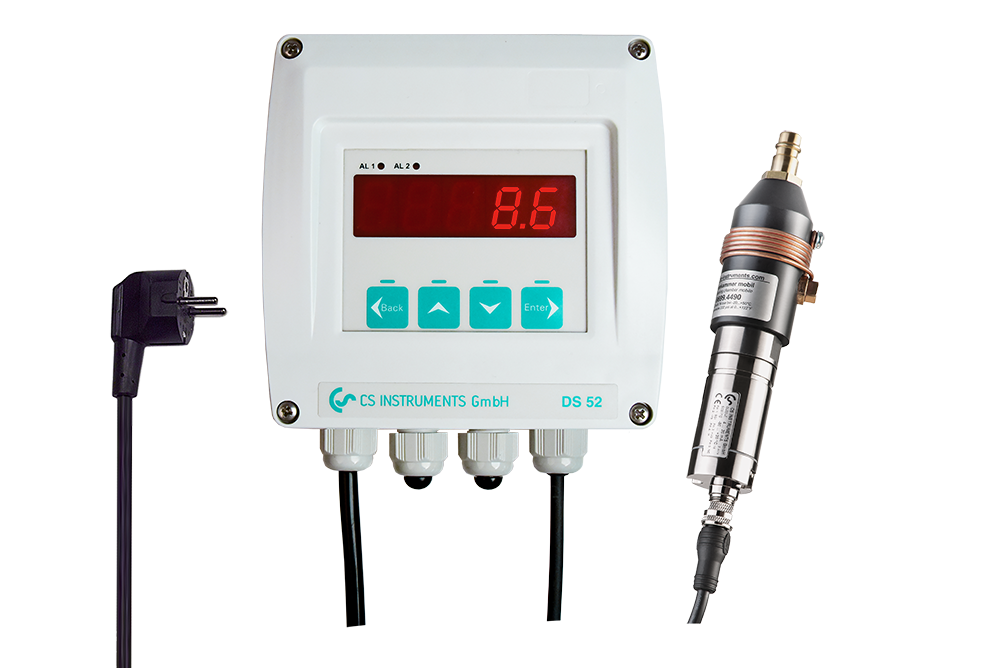

We recommend our DS52 dew point alarm set as a simple and reliable dew point alarm.