OIL CHECK 500

The monitoring system for high-precision measuring of the Vaporous Residual oil content of Compressed air and Nitrogen.

The quality of gas or compressed air within a system depends to a large extent on the continuous monitoring of the residual oil content and the number of particles. Our systems for determining the residual oil content and measuring the particles in compressed air and gas are available both in a stationary and in a mobile version. In this way, we offer the right system for every application to meet the requirements of ISO 8573 as easily as possible.

The monitoring system for high-precision measuring of the Vaporous Residual oil content of Compressed air and Nitrogen.

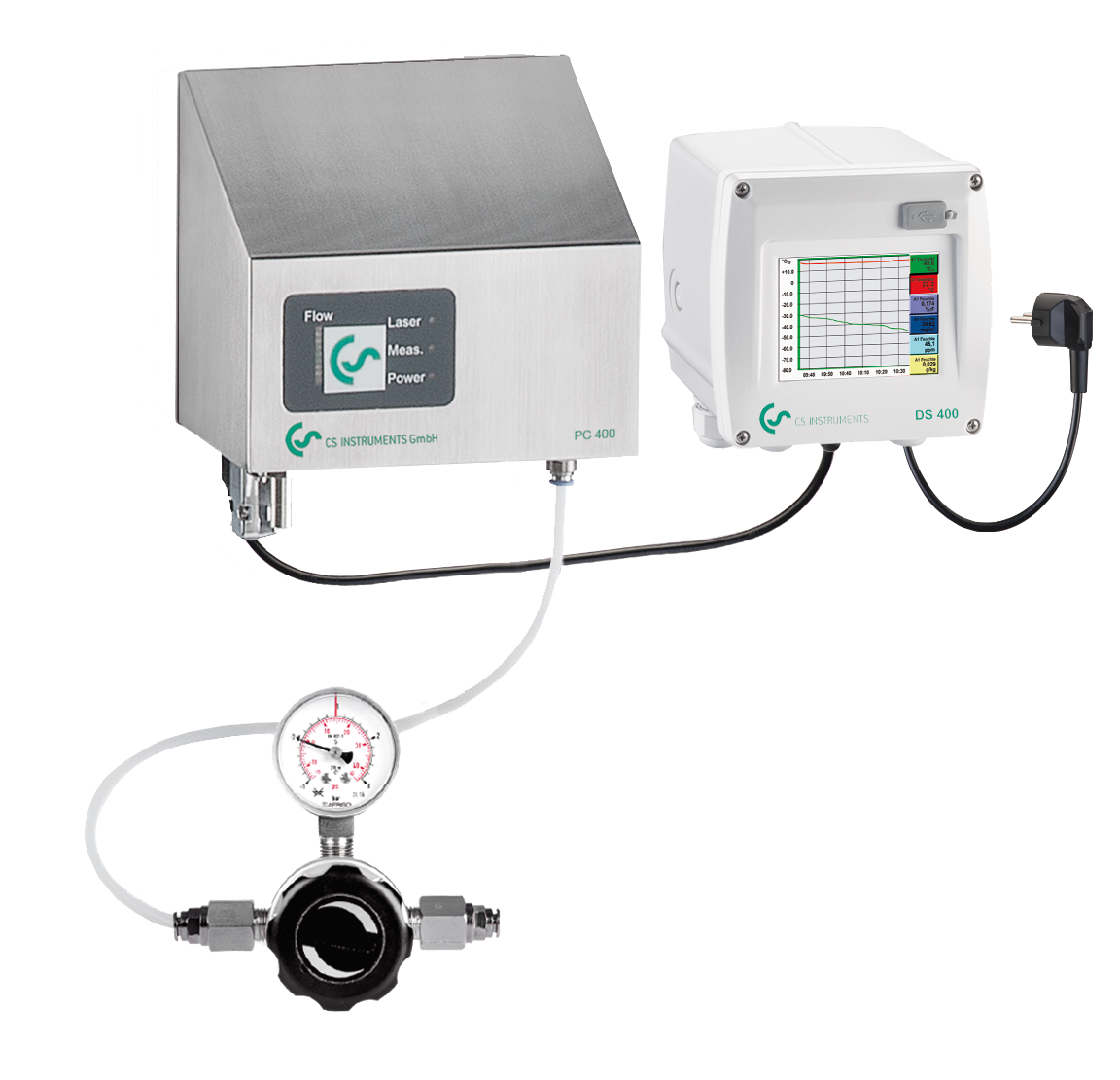

The residual oil content sensor OILCHECK measures the vaporous residual oil content in the compressed air. For a mobile solution we offer you a combination with the particle counter PC 400 and mobile chart recorder DS 500 mobile.

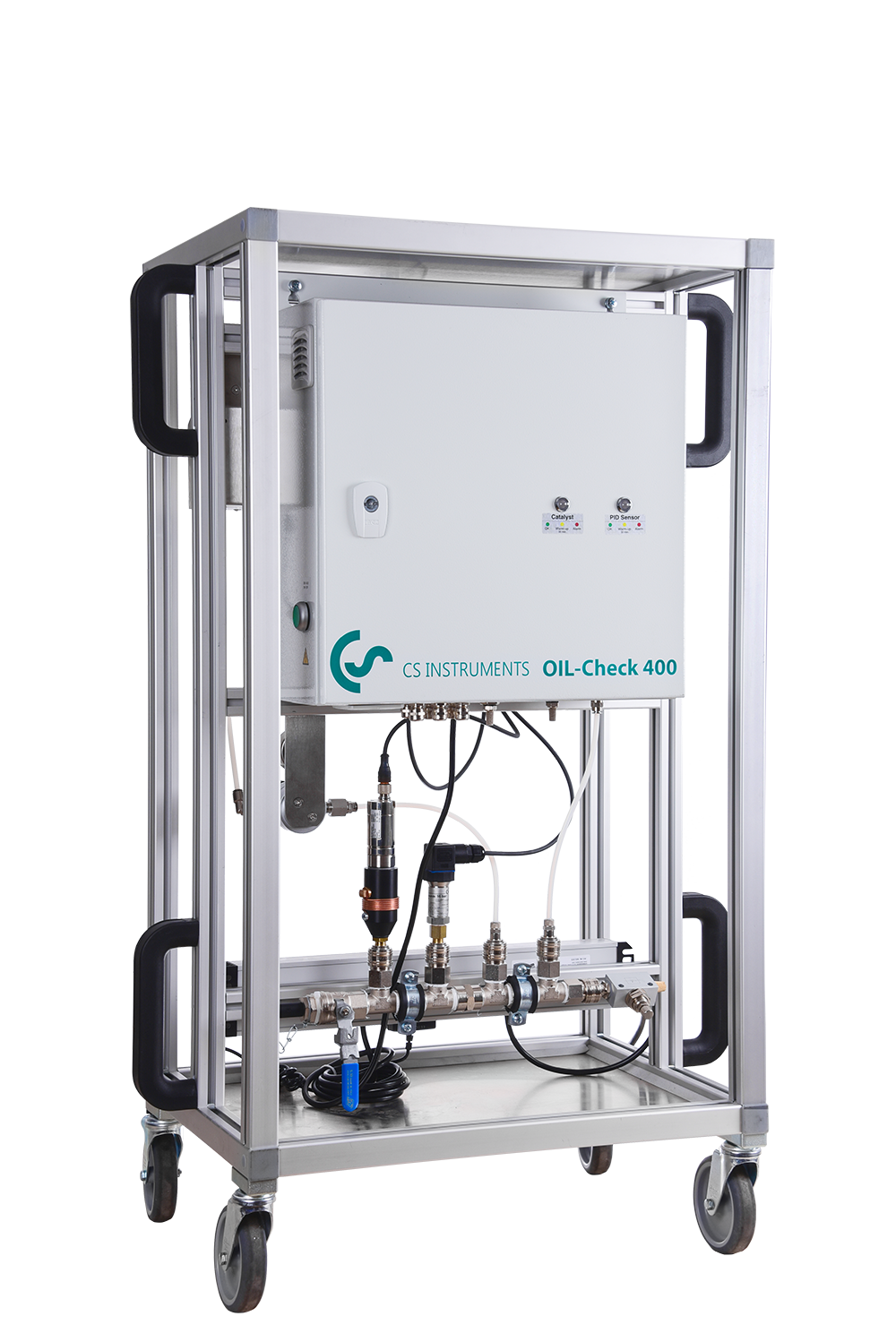

The residual oil content sensor OILCHECK measures the vaporous residual oil content in the compressed air. For stationary solution we offer you a combination with the chart recorder DS 400.

PC 400 particle counter up to 0.1 µm for compressed air and gases in a service case.

The highly precise optical particle counter PC 400 measures particles from a size of 0.1 µm and is therefore suitable for monitoring of the compressed air quality class 1 ISO 8573.

Compressed air is generated by a compressor compressing ambient air. If impurities in the compressed air come into contact with the end product, this can lead to higher reject rates. This often turns what at first glance appears to be a cost-effective solution into a very expensive method of compressed air generation. It is therefore essential for the user to treat the compressed air after it has been generated, as this air contains water, oil, dust particles and other impurities. Depending on the compressed air quality required, these ingredients can cause problems during production and increase operating costs.

CS INSTRUMENTS offers both portable and stationary measuring devices for compressed air quality measurement in accordance with ISO 8573-1: