Four steps to analysing compressed air

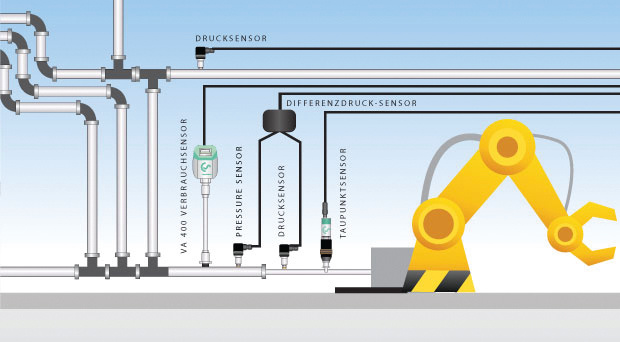

The first step is to install precise consumption meters and flow meters for Compressed air at the crucial points in order to obtain reliable measurement data. The devices are installed directly in the main lines of the compressed air station (in the compressor room). The first step is to record the compressed air consumption in the main supply lines, ideally using an Intelligent chart recorder. The compressed air lines that branch off to the individual end users of the compressed air are only analysed in a second step.

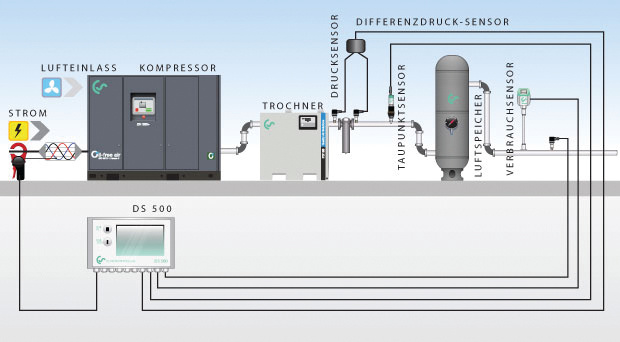

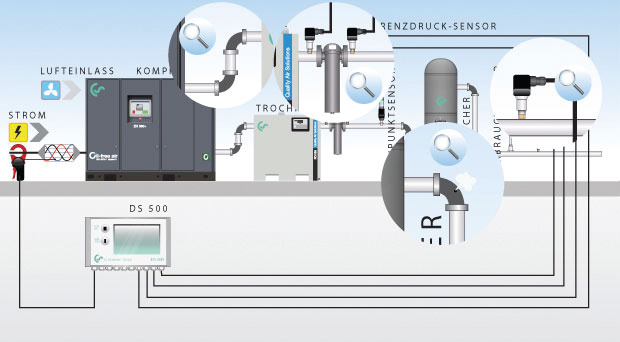

As shown in the example, the DS 500 Intelligent chart recorder is used to measure and record the compressed air consumption with the VA 500 Consumption sensor, the dew point or Pressure dew point with the FA 510 Dew point sensor, the current or energy consumption with a CS Current clamp and additionally the pressure with a CS Pressure sensor, directly at the Compressed air generation in the compressor room.

In practice, such a Compressed air measurement should be carried out for at least a complete week. Ideally from Friday to Friday in order to obtain the consumption data of the Compressedair systems for a complete production period. Compressed air leaks become transparent very quickly, especially at the weekend. During the non-production period, compressed air consumption should be close to "zero m³/h", which is unrealistic in practice. Compressor load behaviour at the weekend, when the compressors are only running to pressurise the Leakages, and peak compressed air consumption at the start of the week become visible.

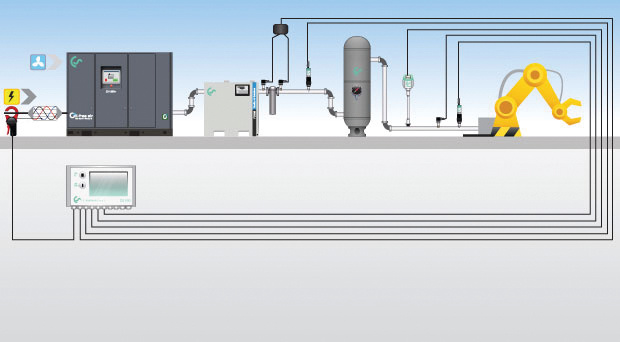

With the help of the DS 500 Intelligent chart recorder, CS INSTRUMENTS offers customised solutions.