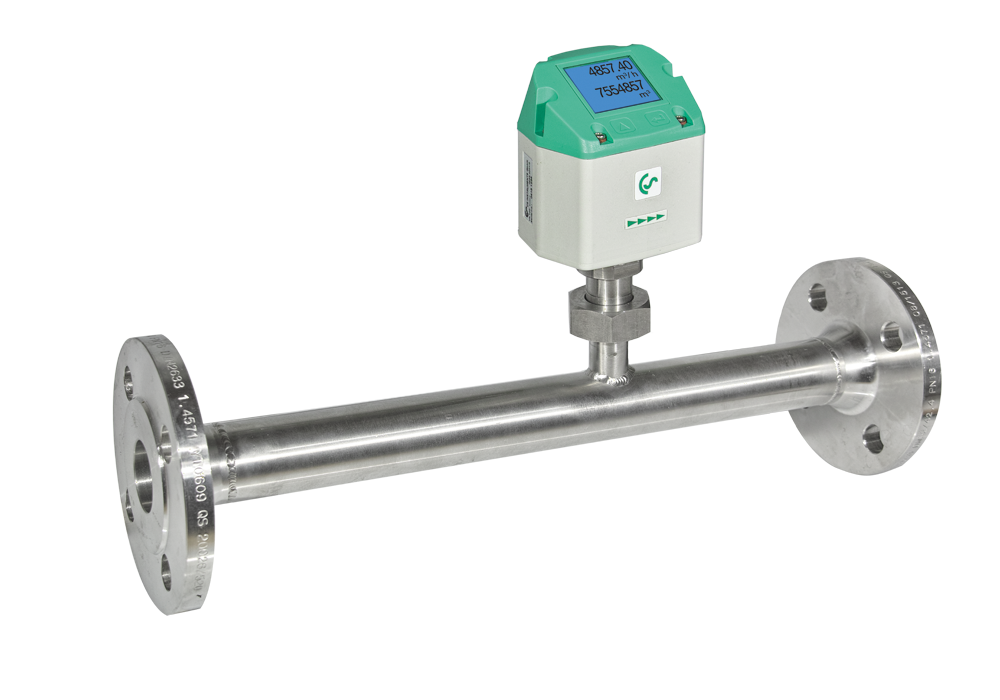

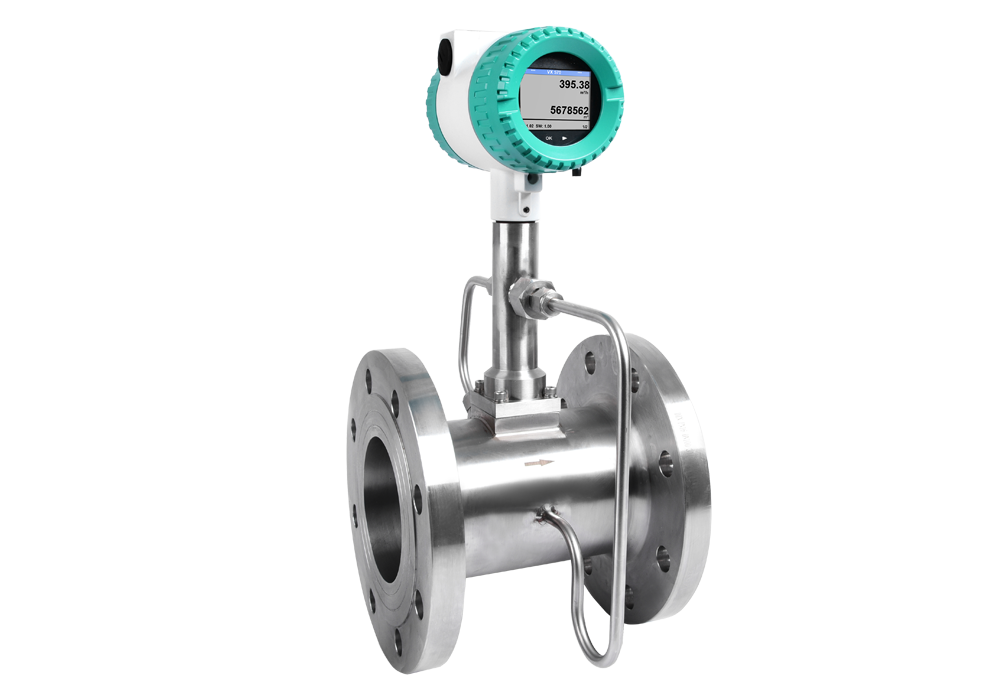

VA 500 - Flow meter for compressed air and gases

RS 485 interface, Modbus RTU, 4...20 mA analogue output for m³/h, Pulse output for m³.

Not quite sure which flow meter is right for your specific application? Then simply contact us in advance. As a leading supplier of flow meters and consumption measurement systems, we will be happy to help you find the right flow measurement system for your compressed air or gas system and provide you with a non-binding offer.

RS 485 interface, Modbus RTU, 4...20 mA analogue output for m³/h, Pulse output for m³.

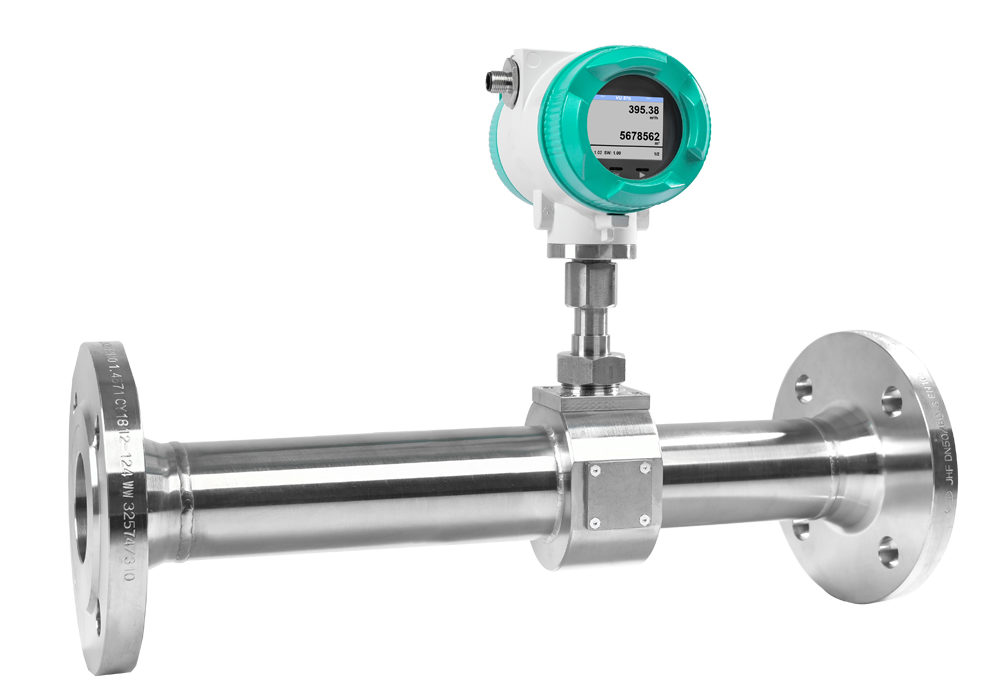

for compressed air and gases. New digital electronics - improved accuracy.

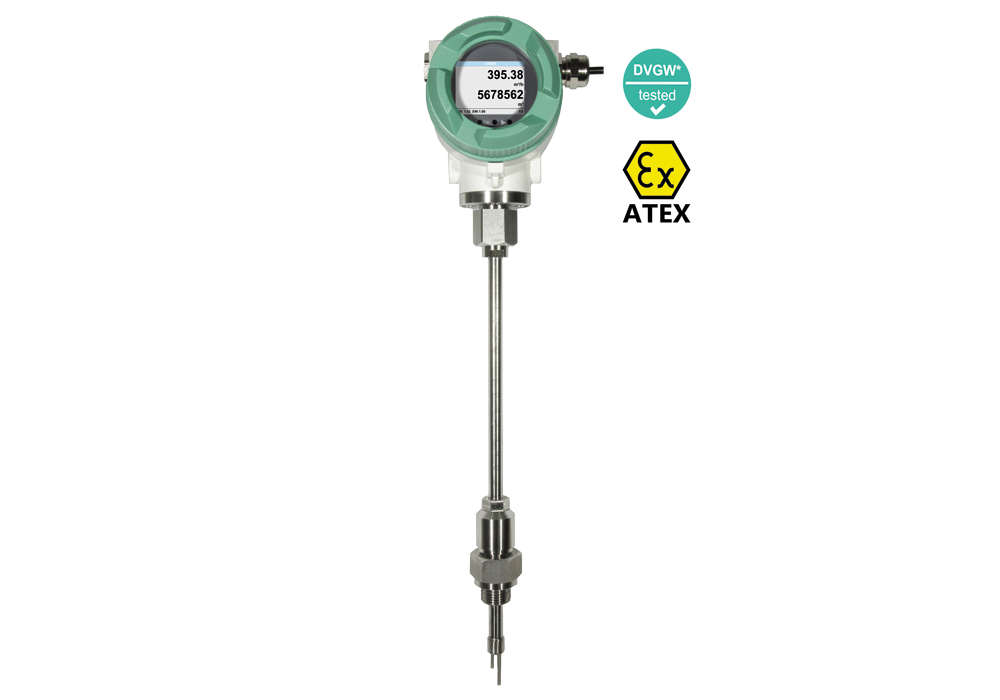

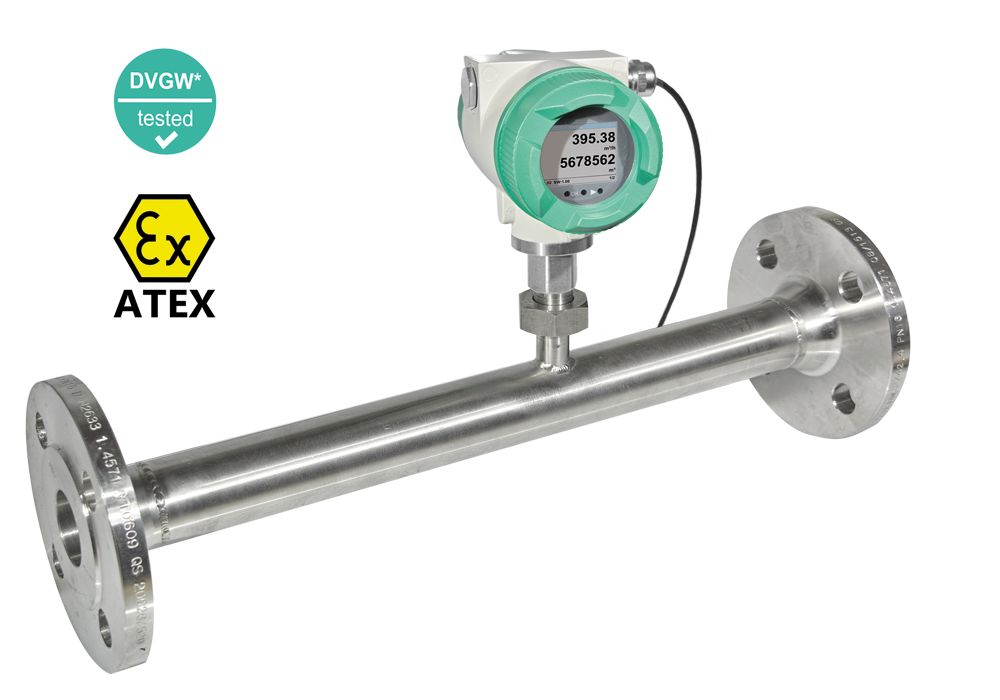

Insertion type sensor for demanding industrial applications, with ATEX approval for Ex zones or DVGW approval for use in natural gas.

ATEX approval for hazardous areas and DVGW approval for use in natural gas.

The ideal device for energy monitoring, in compressed air and other gas systems, with many consumers.

The ideal device for energy monitoring in compressed air or nitrogen with many consumers.

For measuring immediately downstream of the compressor in moist air up to +180 °C

For technical gases and mixed gases - independent of the gas composition

for technical gases, mixed gases - also with changing composition, steam and liquids

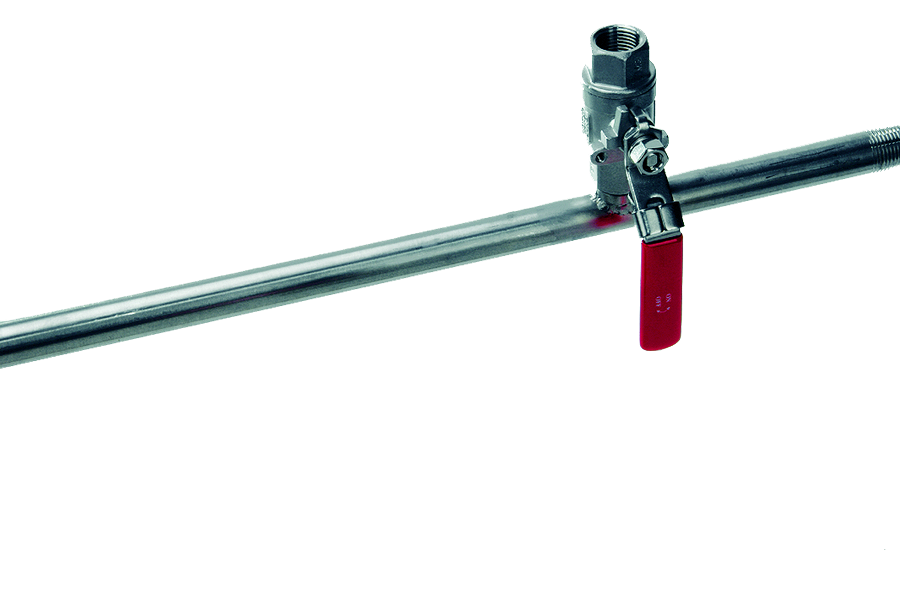

Measuring section made of stainless steel 1.4301 incl. ball valve, up to DN 65 (R2 1/2") with external thread, from DN 80 with weld neck flange according to DIN 2633.

If there is no measuring site with 1/2" ball valve present it can be set up by means of spot drilling collars.

By means of a special drilling device a measuring site with 1/2" ball valve can be easily set up within a few minutes.

The supplementary device "high-pressure protection" serves for a safe installation and fastening of the CS sensors VA 500 under pressure.

enables a quick, easy and accurate measurement of the wall thickness of pipes.

The products of CS INSTRUMENTS GmbH have been leading in the field of consumption measurement and flow measurement of gases for years. Customers all over the world appreciate the professional support and development spirit behind our products. Through international subsidiaries and a constantly growing, worldwide sales and service network, we provide our customers with the latest measuring technology and ensure optimum all-round support. For many applications, we offer specially developed and tried-and-tested systems for consumption and flow measurement which, in combination with our specially developed software solutions, are both uniquely effective and efficient.

For example, our VA550 (insertion version) and VA570 (version with integrated measuring section) flow sensors have been specially developed for use in harsh industrial environments. Thanks to the robust, impact-resistant die-cast aluminium housing, these flow sensors can be easily installed outdoors (IP65). We can also provide ATEX or DVGW approval on request.

All our flow meters work according to the calorimetric principle and measure the thermal mass flow or standarised volume flow directly. Additional temperature and pressure compensation is not necessary. The standard volume is a common unit of volume measurement that is used to compare gas volumes at different pressures and temperatures. In order to fulfil various standards, the reference conditions can be set directly on the display of all our sensors. This means that the flow meter provides the consumption directly in the set standard. While ISO 1217 (1000 mbar, 20 °C) is generally applied in the compressed air sector, DIN1343 (1013 mbar, 0 °C) is used for technical gases.

Is this all too complicated for you? No problem! We are sure to have the right device for your application. Simply contact us, we will be happy to advise you individually on your application and work with you to find the right device.

| ✓ Air / compressed air | ✓ Carbon dioxide (CO2) | ✓ Nitrous oxide (N2O) |

| ✓ Nitrogen (N2) | ✓ Oxygen (O2) | ✓ Propane (C3H8) |

| ✓ Argon (Ar) | ✓ Hydrogen (H2) | ✓ Natural gas / biogas |

| ✓ Helium (He) | ✓ Methane (CH4) | ✓ Vacuum |

A factory calibration certificate is always included with our devices. ISO certificates, which are traceable to the national standard, are also available as an option. In contrast to many other measuring methods, the pressure loss caused by our flow measurement is negligible.

Each flow meter can be equipped with various interfaces to ensure connection to your control technology, data loggers or evaluation devices. These include, for example, 4...20mA, pulse, Modbus RTU, M-Bus or Ethernet. The thermal mass flow sensors can also be used to cover a very wide range of different applications and media(compressed air, carbon dioxide, vacuum, nitrogen, oxygen, ozone, natural gas, hydrogen, argon, helium, biogas, etc.).

In addition to flow measurement, our sensors can also be used to measure leakage quantities. In this way, they provide the user with information on possible energy savings. The insertion version is the ideal flow meter for existing compressed air and gas lines and can be easily installed and removed under pressure via a ½" ball valve. The flow sensor is available with different shaft lengths and can also be used in very large pipelines > DN 1000 or rectangular ducts.

With three company locations in Germany, Austria and Switzerland and an extensive network of partners, our experts are always available to answer your questions and concerns.