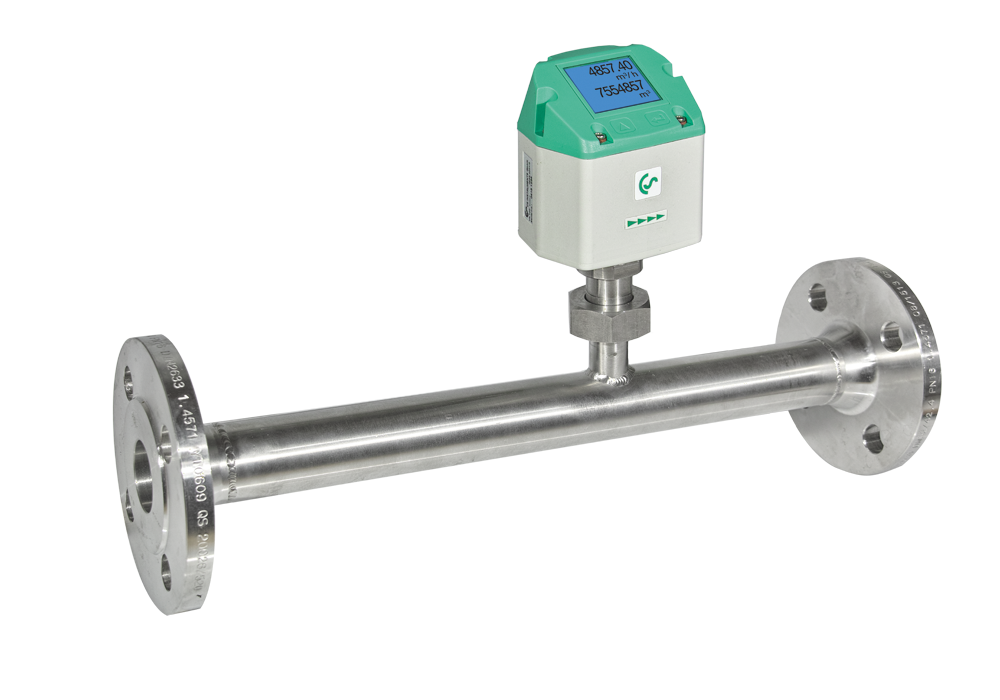

VA 520 - Thermal mass flow meter for flow measurement

for compressed air and gases. New digital electronics - improved accuracy.

Mixed Gases are used to create a protective atmosphere during gas welding. Welding gases, which consist of a mixture of argon, carbon dioxide and oxygen in various proportions, create an inert atmosphere in the welding environment and prevent the welding quality from deteriorating.

Welding gas consumption is a serious cost factor, so controlling the flow or consumption of this gas is always a way of controlling costs.

If the welding gas is interrupted or cut off for any reason, the continuation of the welding process will result in a deterioration of the welding quality. If the gas flow is interrupted, the dry contact (Alarm) is detected by the VA520 Flow meter and the required warning is issued immediately. The welding process can thus be stopped in good time before the welding quality suffers.