Flow monitoring of the natural gas consumption of melting furnaces

We are pleased to present an application in the field of process optimisation in which CS INSTRUMENTS has made a significant contribution to increasing Efficiency. In cooperation with a renowned foundry, we had the opportunity to use our VA 570 Thermal mass flow meters to monitor the natural gas consumption of the melting furnaces.

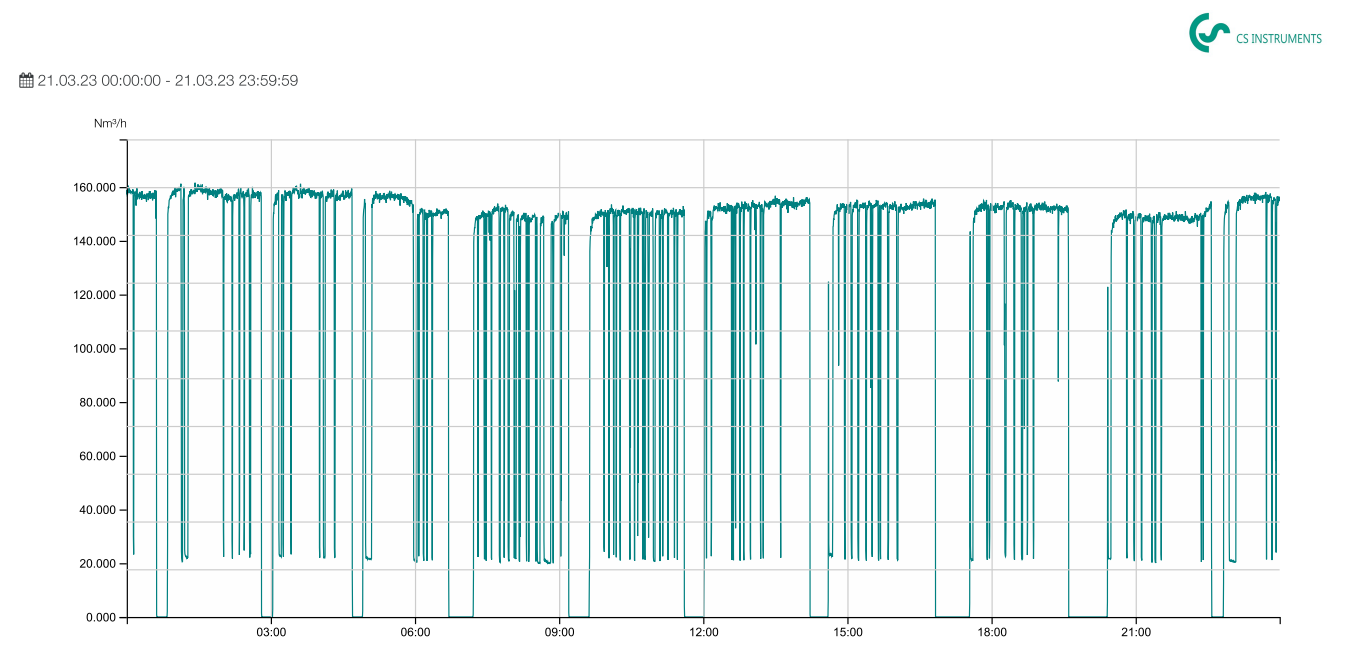

Prior to the implementation of our technology, the furnaces were operated without flow monitoring, resulting in natural gas consumption based on experience and the individual gut feeling of the employees. After some burners were replaced due to age, the foundry noticed quality issues and unexplained fluctuations. This is where we recognised the potential of our technology.

The insights we gained were extremely revealing. Accuracy measurements showed that identical annealing furnaces with the same burner types consumed different amounts of Natural gas because they were manually set differently. In addition, we were able to identify Leakages in burners that had been switched off, and we detected fluctuations of up to 10% in consumption between day and night operation.

By precisely adjusting the burners using our VA 570 mass flow sensors, we were able to reduce the natural gas consumption of the annealing furnaces by an impressive 25%.

Our technology enables efficient monitoring and optimisation of processes, resulting in significant cost savings.

This success story underlines the power of our broad product portfolio and shows how CS INSTRUMENTS helps to improve processes to significantly reduce industrial Energy consumption.