Compressed air quality

Compressed air quality measurement plays a key role in numerous industrial processes in which compressed air is used as a crucial operating material. The quality of compressed air affects not only the performance of machines and tools, but also product quality, especially in industries such as food production, pharmaceuticals and electronics manufacturing. Measuring devices for compressed air quality measurement are crucial here to ensure that the compressed air meets the required standards at all times.

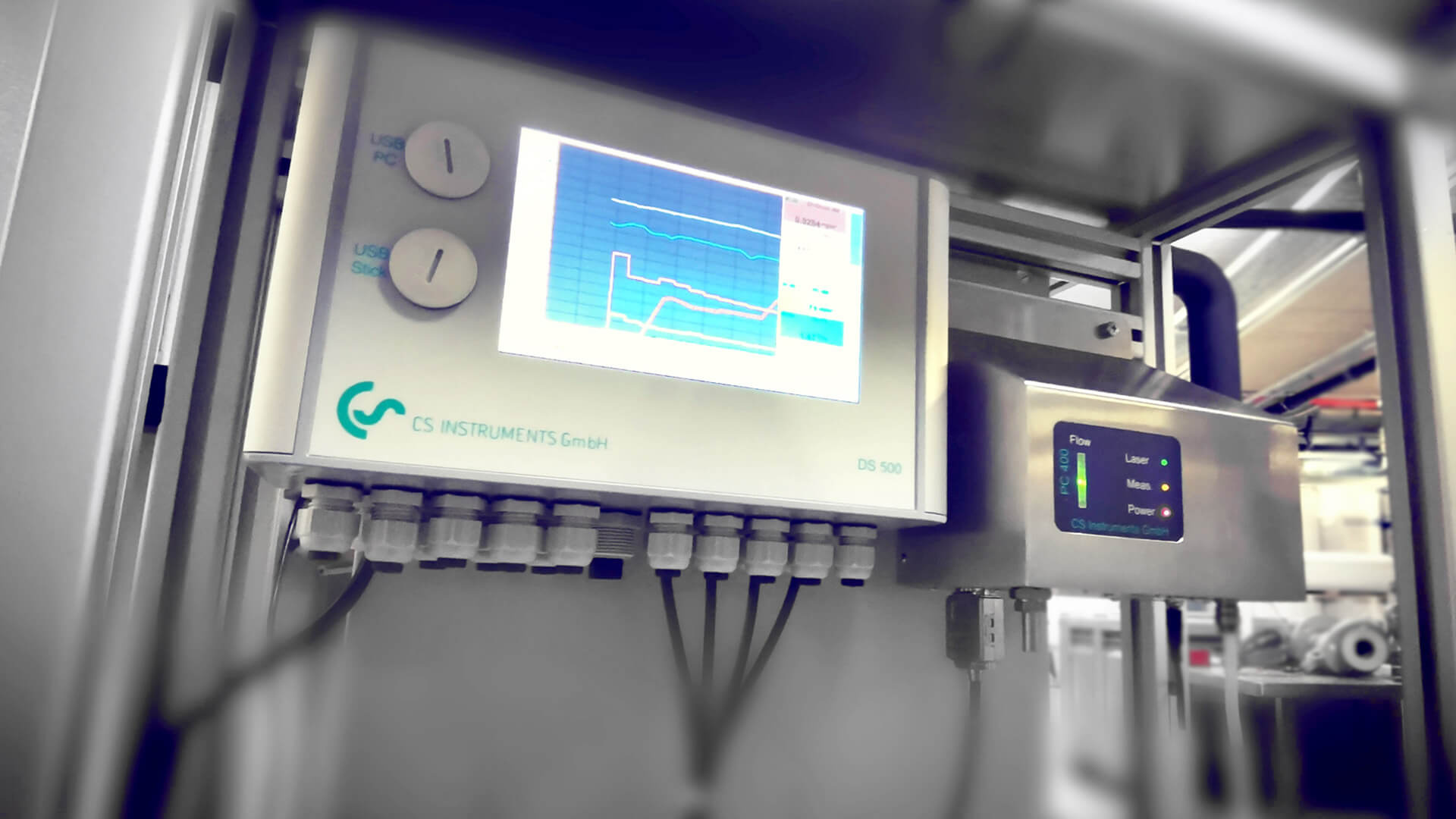

A basic measuring instrument in this context is the particle counter. It monitors the concentration of solid particles in the compressed air and ensures that it is within acceptable limits. Particles in compressed air can not only impair the efficiency of machines, but can also lead to production errors if they enter sensitive production environments.

Another important measuring device is the oil mist monitor. This monitors the oil content in the compressed air and ensures that it is below the permissible limits. In industries where absolute cleanliness is crucial, such as medical technology, Accuracy monitoring of the oil content is essential for obvious reasons.

However, in this section we have collected other example applications or industry examples where, in our experience, monitoring compressed air quality is crucial.