DP 510 - Portable dew point meter with third-party sensor

Disposes all functions of our DP 500 and comes with an additional - freely assignable - sensor input.

If plastic granulate is not optimally dried before injection molding, this can have a variety of negative effects on the end product. For example, processing plastic granulate that is too Humidity can lead to quality problems in the end product, but also to problems during the injection molding process itself.

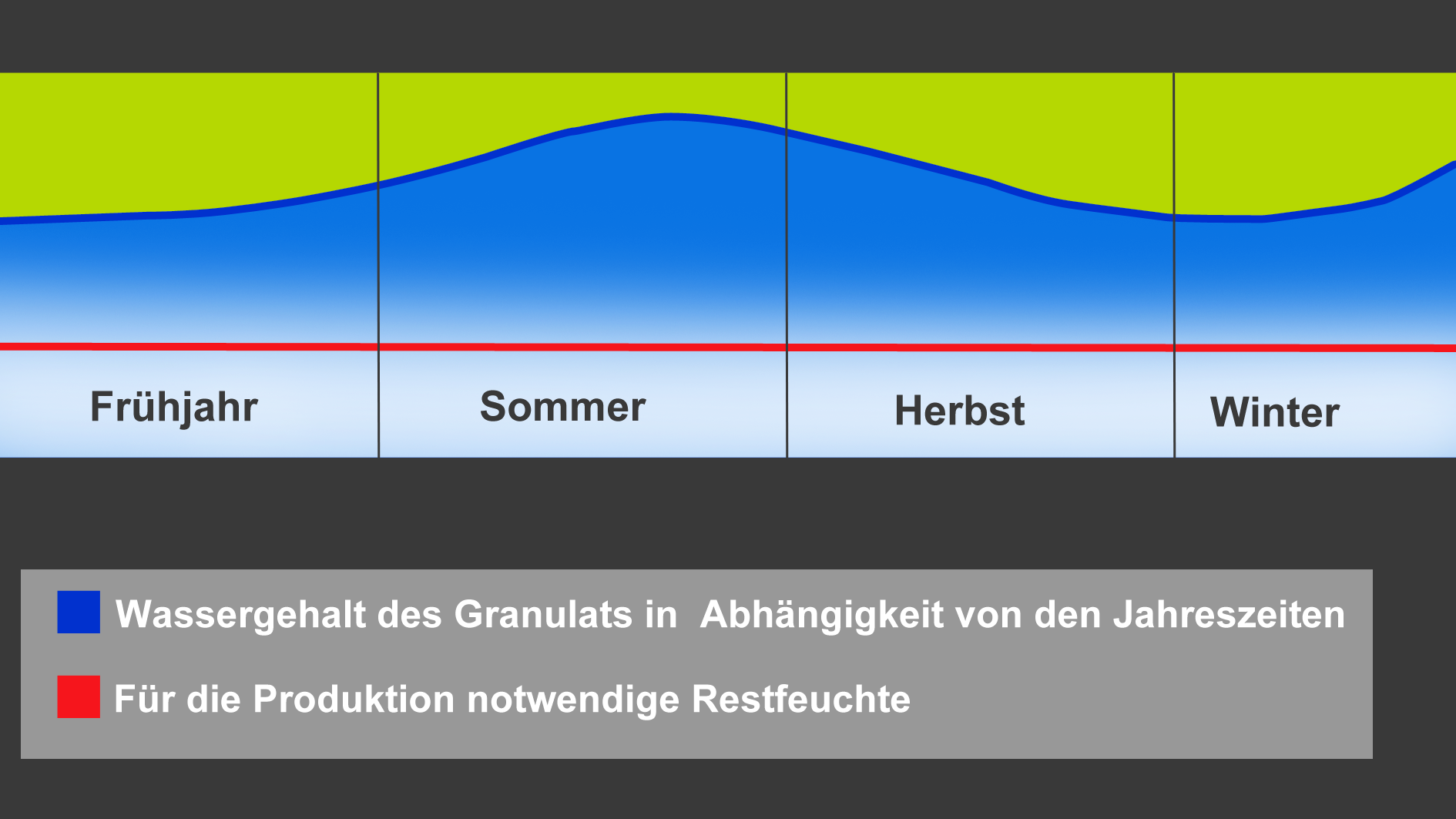

During transportation and storage, plastic granulate can absorb more or less moisture, depending on the plastic in question. Many plastics themselves are hygroscopic and literally attract moisture. The water vapor can even penetrate deep into the molecular structure, which is referred to as core moisture. Environmental influences have the greatest impact here and so the moisture content in the plastic granulate varies depending on the time of year.