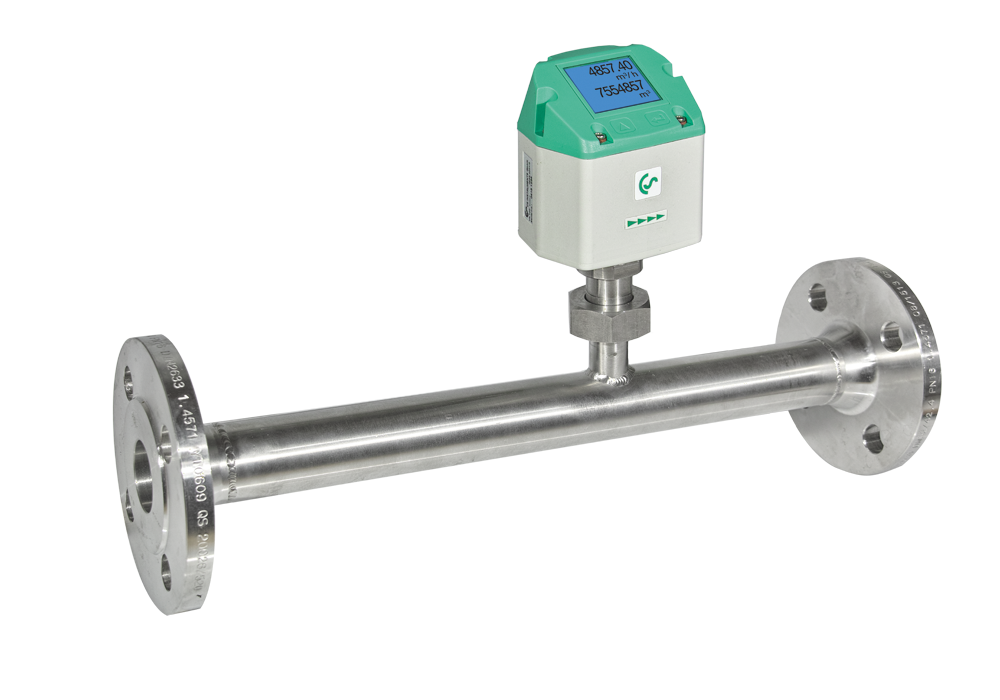

VA 520 - Thermal mass flow meter for flow measurement

for compressed air and gases. New digital electronics - improved accuracy.

Many people do not realize that Compressed air plays a very interesting role in packaging in the industry. There are different types of packaging machines that use compressed air to form, fill, seal or transport packaging.

CS INSTRUMENTS helps to solve various measuring tasks, reduce Energy consumption and optimize cost and quality parameters with intelligent Measuring technology for Compressed air / gases.

These machines use compressed air to form, fill and seal packaging. For example, compressed air sealing machines can be used to seal flexible packaging such as pouches or tubular bags. Compressed air is also used in vacuum packaging machines to create the vacuum in the packaging and protect the product.

These machines use compressed air to stack packaging such as cartons or containers onto pallets. Compressed air can be used to drive vacuum suction cups that grip the packaging and place it on the pallet.

These machines use compressed air to apply labels to packaging. Compressed air can also be used to stabilize the packaging during the labelling process.

Compressed air can be used to transport packaging from one station to another. For example, pneumatic conveyor belts can be used to transport packaging from the filling line to the packaging machine.

It is fast and efficient, has a high level of precision and is reliable when handling packaging.

Compressed air that comes into contact with food or pharmaceuticals should meet certain quality parameters in order not to contaminate the end product. These parameters and limit values are described in ISO 8573-1, for example. Contaminants such as residual oil, Particles or residual moisture in the Compressed air can lead to quality fluctuations or contamination of the end product.

In addition to Measuring Compressed air quality, the compressed air consumption of the machine should not be neglected. The cost of the compressed air used to package the product could, for example, be passed on to the end product. Leakages in the packaging machines could also lead to increased compressed air consumption, which can very quickly result in very high costs. With continuous monitoring of the parameters of volume flow and Total consumption, e.g. with Flow sensors in compact design from CS INSTRTUMENTS, this can be monitored and, if necessary, detected in good time.