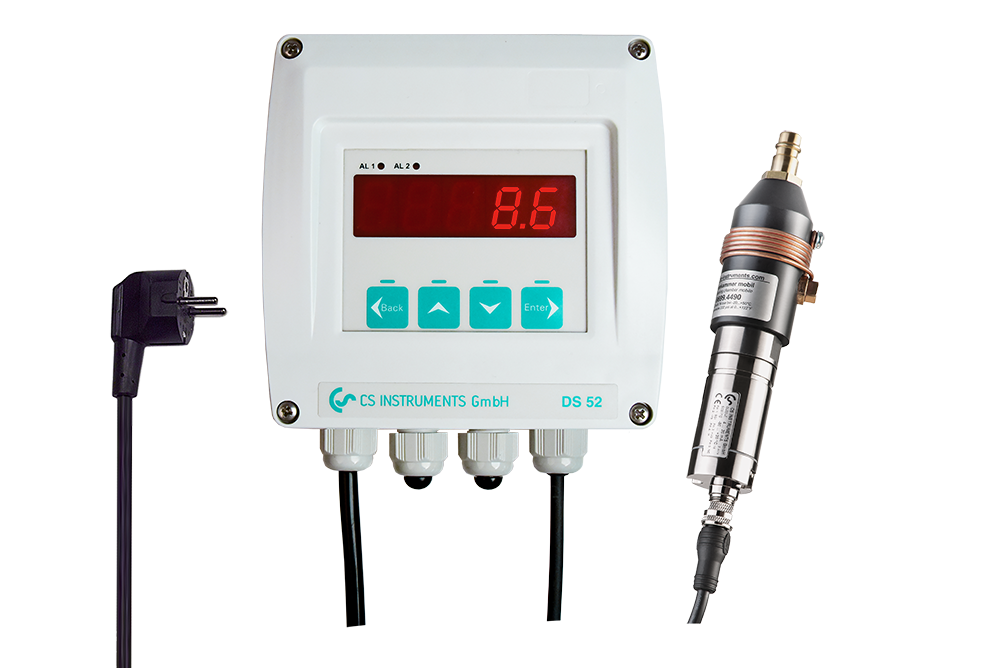

Dew point measurement DS 52-set for refrigeration dryers

with the digital process meter DS 52 and the dew point sensor FA 510 with a measuring range from -20 to 50°Ctd.

Dew point monitoring in the compressed air line to ensure dryer performance and automatic flushing for companies in the fruit and vegetable sector.

The Dew point of a Refrigeration dryer is usually around 3-5° Ctd. There are a number of factors that can lead to an increase in the Dew point, which can result in water entering the system and causing significant technical and economic problems.

By installing a Dew point sensor downstream of the dryer, you can ensure that you receive an Alarm when a dryer problem occurs so that you can act quickly before the water enters the system.

The big problem in this sector is the lack of awareness among users of the high costs that can be incurred by water in the compressed air line.

Maintaining good Compressed air quality reduces costs for all pneumatic elements in a system

Both kits are plug-and-play systems (everything is pre-wired), both contain two alarm relays. As the more advanced device, the DS 400 is able to connect three additional sensors and record their measurement data.