DP 510 - Portable dew point meter with third-party sensor

Combines all the functions of the DP 500 with an additional, freely assignable sensor input.

For compressed air up to 16 bar

Order no.: 0699 3390

Combines all the functions of the DP 500 with an additional, freely assignable sensor input.

Ideal for Dew point measurement of Refrigeration dryers and Desiccant dryers.

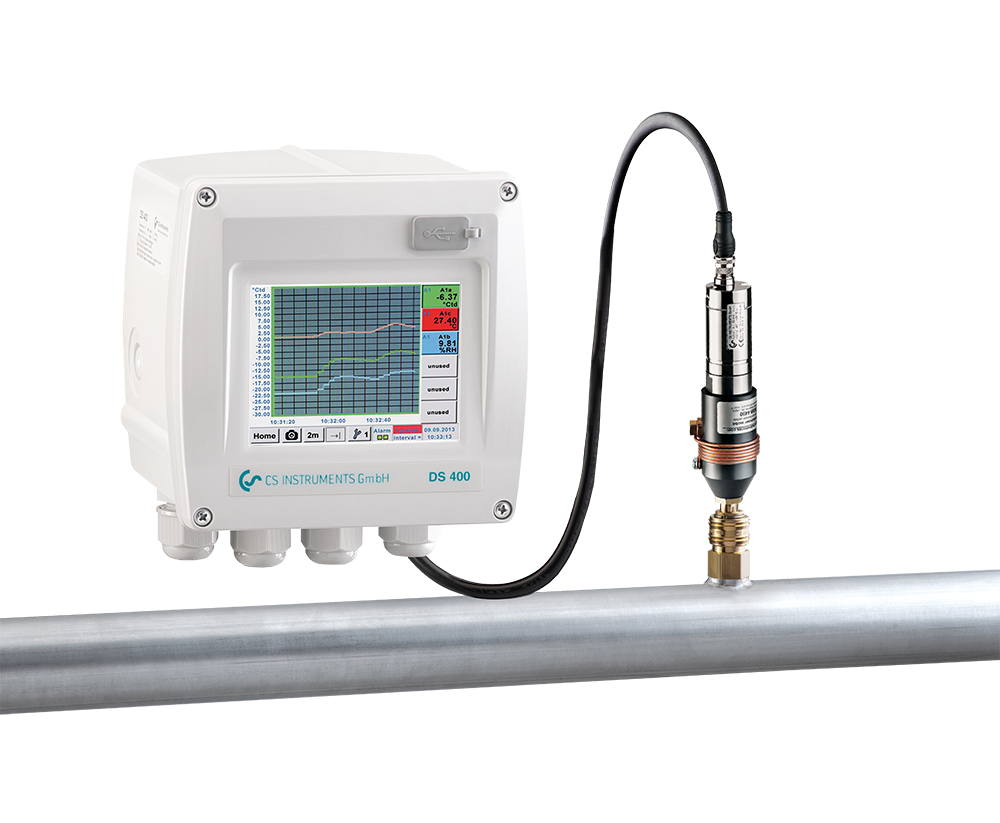

Dew point sensors for various types of dryers with integrated Display and alarm relay.

For residual moisture measurement from -80 to 20°Ctd. New: With Modbus RTU interface.