FA 510/515 - Dew point sensor for refrigeration dryers

Dew point measurement from -20 to 50°Ctd. New: with Modbus-RTU interface.

Compressed air is a versatile and reliable energy source that has become an indispensable part of modern production processes. Depending on the respective application, different requirements are placed on a compressed air system. Maintaining a certain moisture content or dew point / Pressure dew point is the basic prerequisite for any process to ensure that the system continues to run smoothly.

CS INSTRUMENTS GmbH & Co. KG has developed the DS 400 Pressure dew point measuring device with many new advantages especially for the measurement of humidity in compressed air and gases.

Compressed air is usually produced from ambient air, which is drawn in, compressed with pistons or screw compressors and then dried to a greater or lesser extent. The aim is to produce dry, oil-free and low-dust Compressed air with as little effort as possible. Oil residues and dust particles can be removed using complex filter systems. Humidity, on the other hand, must be reduced by means of dryers (Refrigeration dryers, Membrane dryers, Desiccant dryers, etc.), which ideally operate under load-independent control.

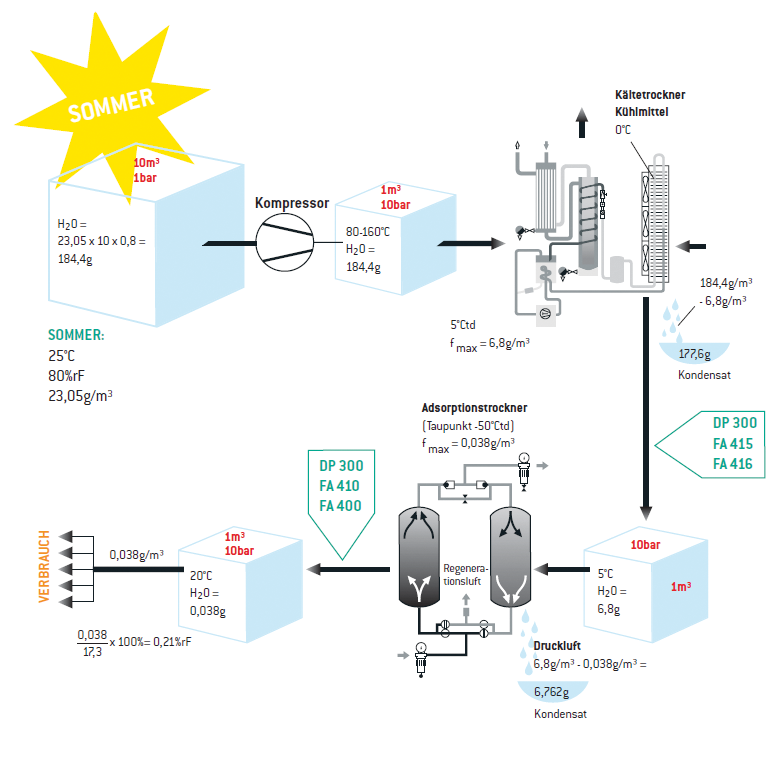

The higher the Temperature and the larger the volume, the more water vapour the air can bind. Conversely, compressed air has less ability to bind water vapour. A Compressor compresses atmospheric ambient air to a fraction of its original volume. At a certain point in the compression process, the water content of the air exceeds the air's ability to bind water vapour. The air is saturated and some of the water precipitates as condensate. Lowering the Temperature further causes even more water to condense. This means that the relative Humidity at the outlet of a Compressor is always 100% and there are also water droplets in the outlet air. The amount of liquid that precipitates under Pressure can be considerable. For example, a 30 kW Compressor with a Humidity of 60% and an ambient temperature of 20°C discharges 20 litres into the compressed air line in eight hours. With large compressors, the value is many times greater.

Compressed air is subject to different requirements depending on the application. Maintaining a certain moisture content is a prerequisite for the entire system to function smoothly in the long term. Most compressed air lines are made of steel or non-galvanised steel. As the corrosion rate increases sharply from a relative Humidity of 50%, this value should not be exceeded under any circumstances. In the case of non-galvanised lines, high Humidity leads to corrosion over time. The rust flakes off over time and migrates to the tapping points. The consequences are, for example, blocked nozzles, defective control elements and production downtime. Expensive repairs and short maintenance intervals are inevitable.

In addition to the problem of corrosion and the consequences described above, the level of Humidity has a direct influence on the quality of the end products. What problems can arise if Humidity is too high? Here are some examples that frequently occur in practice:

| Applications | Particles | Residual water | ||

| KL | µm | KL | DTP | |

| Breathing air | 1 | 0.1 | 1-3 | -70 / -20 °C |

| Spray guns | 1 | 0.1 | 2 | -40 °C |

| Medical technology | 1 | 0.1 | 3-4 | -20 / +3 °C |

| Measurement and control technology | 1 | 0.1 | 4 | +3 °C |

| Conveying food and beverages | 2 | 1 | 3 | -20 °C |

| Sandblasting systems | - | - | 4-3 | +3 / -20 °C |

| General factory air | 3 | 5 | 4 | +3 °C |

| Break open hammer | 4 | 15 | 5-4 | +7/3°C |

Various types of dryers are used in practice to tackle the problem of excessive Humidity. In compressed air technology, the Pressure dew point is the measure of the dryness of the compressed air. The Pressure dew point is the Temperature at which the humidity contained in the Compressed air condenses to liquid water (also called saturation state, 100% relative humidity). The lower the pressure dew point temperature, the lower the amount of water vapour contained in the compressed air

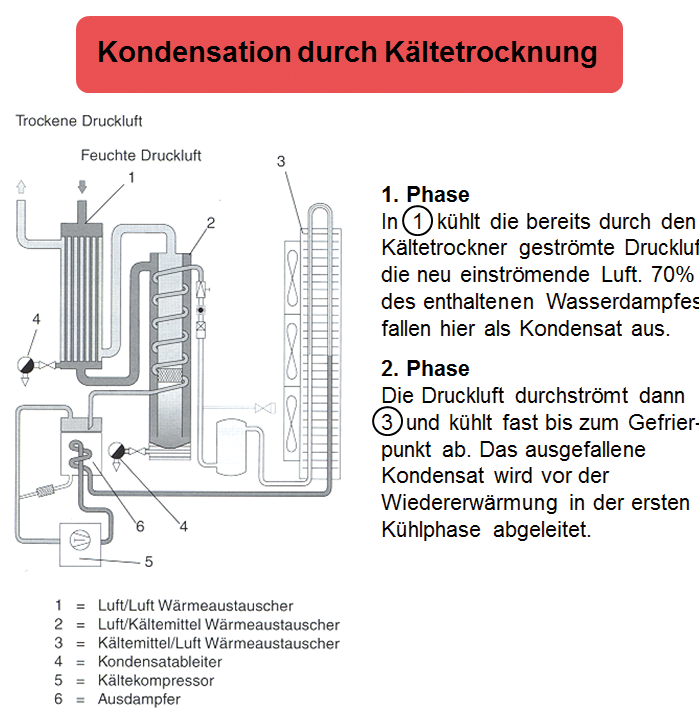

There are different types of compressed air dryers. Refrigeration dryers or Desiccant dryers are the most commonly used. Refrigeration dryers cool the compressed air down to around 2 to 5 °C. The pressure dew point is then also 2 to 5 °C. The Pressure dew point is then also 2 to 5°C. The excess water vapour condenses and precipitates. The air is then heated back up to room temperature.

In most cases, refrigeration compressed air dryers are only monitored by a cooling temperature display. Stationary humidity monitoring has only been installed in large systems or for particularly important applications. However, simply displaying the cooling temperature is not sufficient. Even if the cooling temperature appears to be OK, the following errors can lead to an excessive Pressure dew point:

A failure of the Refrigeration dryer inevitably leads to considerable problems with condensate in the compressed air line. It is particularly problematic (in addition to the problems already mentioned) if the condensate can collect in bag lines and does not drain off by itself. The condensate in bag lines can only be removed again with considerable effort or dried and flushed out using an extremely large amount of compressed air.

This very often leads to increased dew point values at very low Consumptions without any recognisable problems with the Refrigeration dryers. In the long term, it is very difficult for the compressed air manager to find out where the increased dew point values or, in extreme cases, condensate come from.

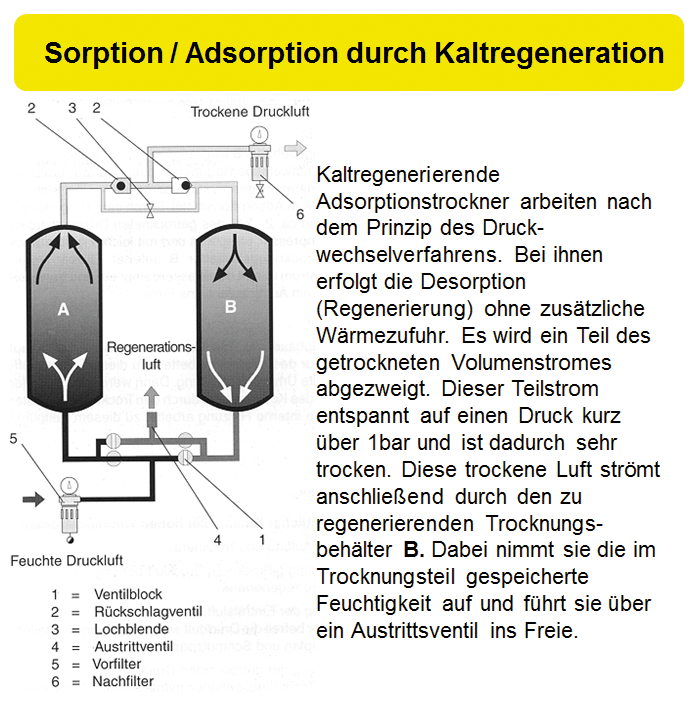

Desiccant dryers work on the principle of attraction between two masses. Water vapour is bound (adsorbed) on the surface of a desiccant. Effective Desiccant dryers can dry Compressed air to a Pressure dew point of -40°C and lower.

Regenerative Desiccant dryers consist of two containers filled with adsorbent. In different processes, one container is regenerated cold or warm, while the other dries the operating air. Depending on the process and operating conditions, the adsorbent must be replaced in a cycle of three to five years.

Certain operating conditions lead to a reduction in the service life of the adsorption agent:

Unique in the world with 3.5" graphic display with touchscreen and print function. An alarm delay can be set for each relay. This means that only limit values that have actually been exceeded for a longer period of time are displayed. The alarm can also be acknowledged. The DS 400 dew point set consists of the DS 400 paperless recorder and the FA 510 dew point sensor including a suitable measuring chamber for measuring the pressure dew point of compressed air and gas up to 16/50/350 bar. For pressures above 16 bar, please use the high-pressure measuring chamber.

The centrepiece of the dew point sensor is the globally proven humidity sensor from CS INSTRUMENTS GmbH & Co KG. In order to achieve fast and accurate measurements, it is necessary that the gas to be measured flows continuously through the humidity sensor. For this purpose, a defined volume flow is blown out at a certain pressure via a capillary division. The standardised plug-in nipple for compressed air lines means that the measuring chamber can be connected to the tapping point without any major installation work.

The major difference to standard paperless paperless paperless recorders is reflected in the simplicity of the DS 400 during commissioning and measurement data evaluation.

The intuitive operation with the 3.5" touchscreen graphic display with zoom function and print button is unique in this price class. With the help of the graphic display with zoom function, the drying process or dew point curve is visible at a glance and stored in the data logger. This allows the user to view the stored measurement data on site at any time, even without a PC. This enables quick and easy analysis of the drying behaviour.

Using the print button, the current screen can be saved as an image file on the internal SD card or on a USB stick and printed out on the PC without additional software. Ideal for documenting the measured values / measurement curves on site. Coloured measurement curves can be sent as an image file by e-mail or integrated into a service report.

The internal data logger enables measurement data to be stored for several years. The measurement data can be analysed on a USB stick or via Ethernet with the convenient CS Soft Basic.