VD 500 – Flow meter for FAD measurement

For measuring immediately downstream of the compressor in moist air up to +180 °C

Efficiency measurement for compressors is an important aspect in the industry as Compressors are used in various Applications to compress air or Gases. Compressor Efficiency is crucial as it has a direct impact on Energy consumption and operating costs. There are various methods for determining the Efficiency of Compressors.

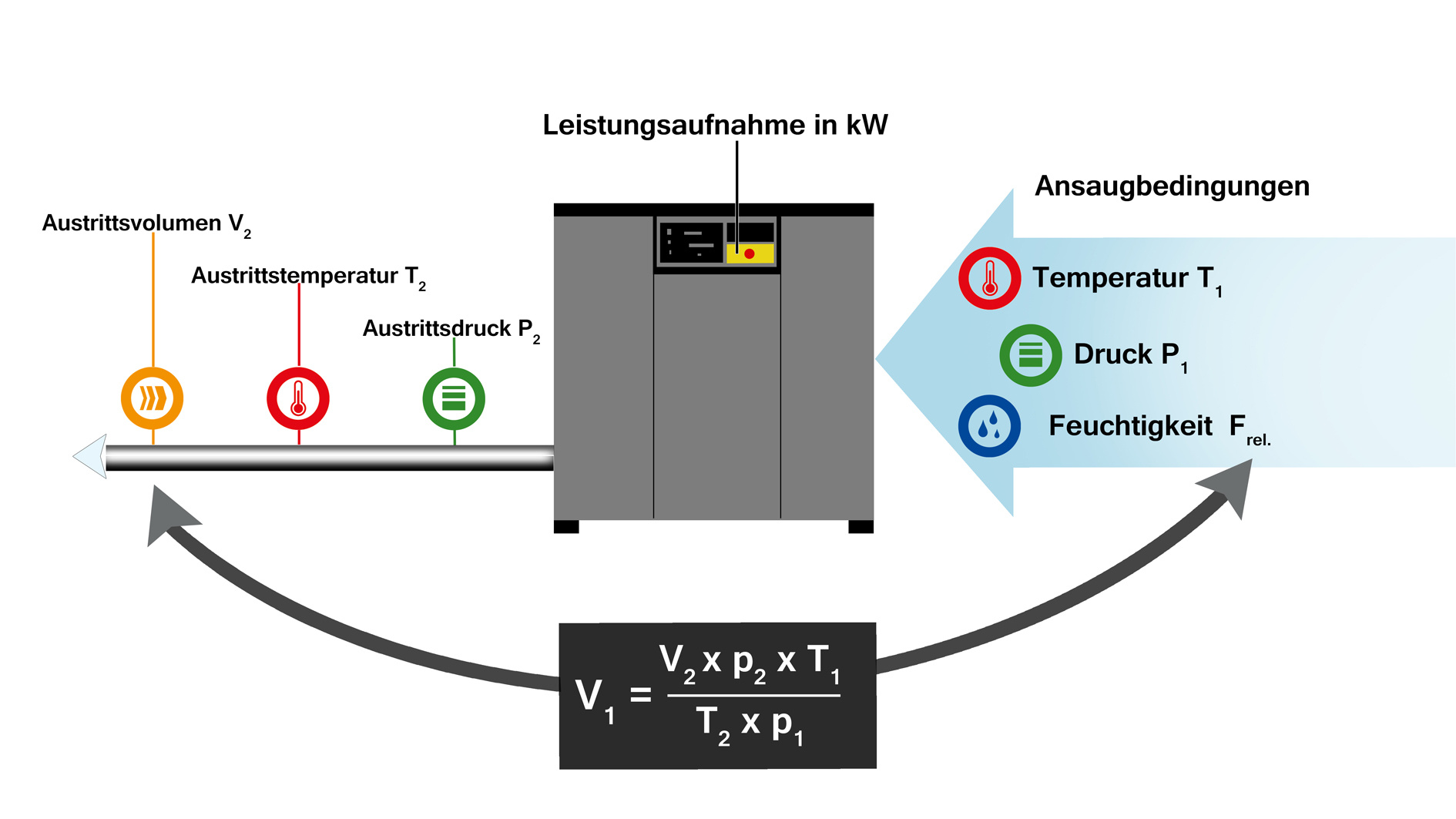

The installation location and climatic conditions must be taken into account when designing compressed air stations. Large temperature fluctuations, e.g. between day and night, lead to uneven compressed air flow.

The choice of the appropriate method for Efficiency measurement depends on the type of Compressor, the available resources and the specific requirements. The results of Efficiency measurements can be used to optimize operation, reduce energy costs and extend the life of the Compressor. It is important to perform regular maintenance and monitoring procedures to maintain a Compressor's Efficiency and detect potential problems early.

Efficiency can be determined in a number of ways, below are two examples:

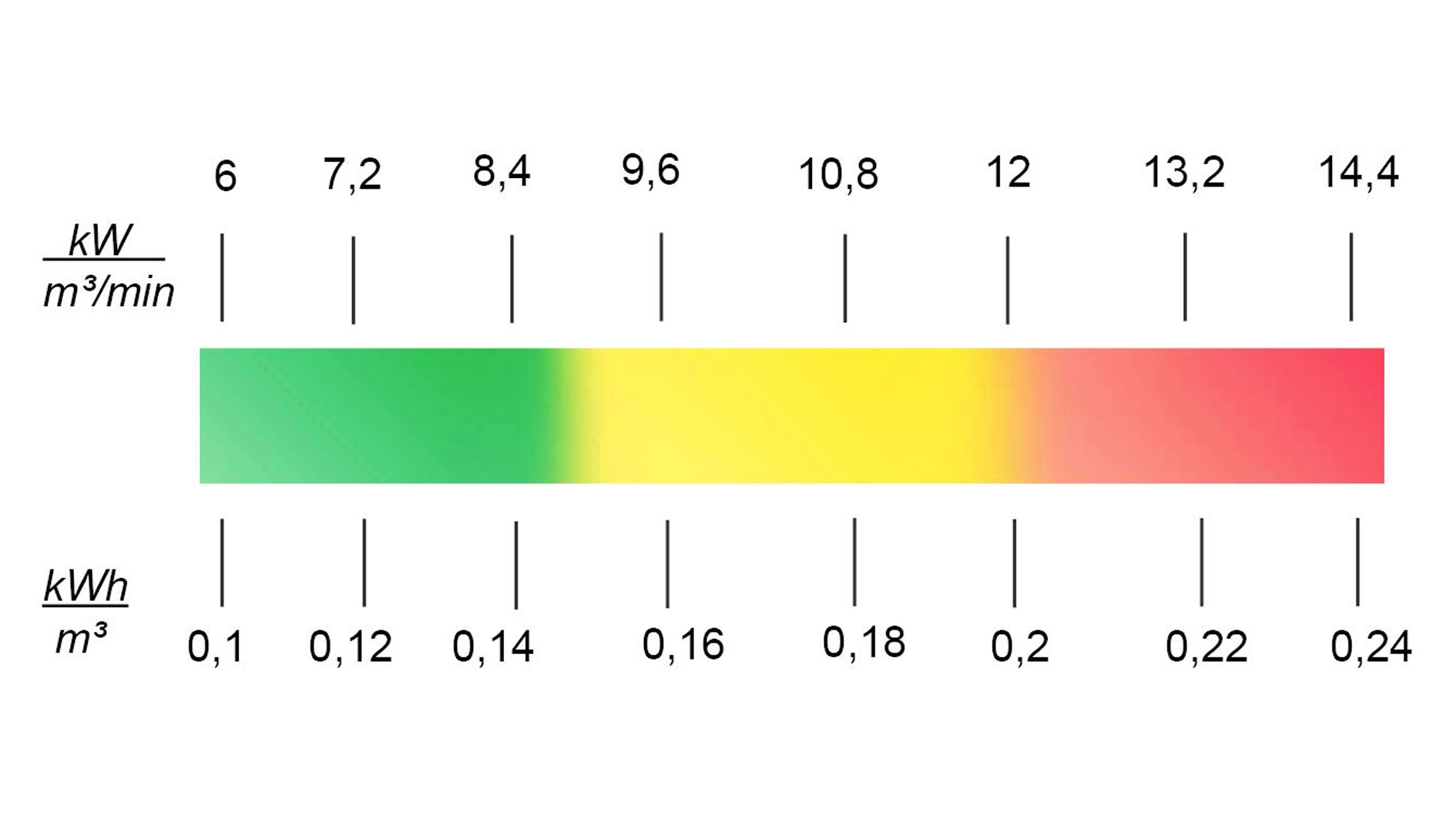

Measuring the power consumption and simultaneously measuring the delivery rate allows the specific power of the Compressor to be calculated. The specific power is calculated using the ratio of the required Energy consumption in kWh to the volume of air delivered in m3 in the same period of time.

Specific output = kWh/m3

The specific performance indicator of the Compressor provides information about the condition of the Compressor. The traffic light shown can be used as an evaluation aid:

A typical specific power requirement of an oil-injected Compressor may be as follows.

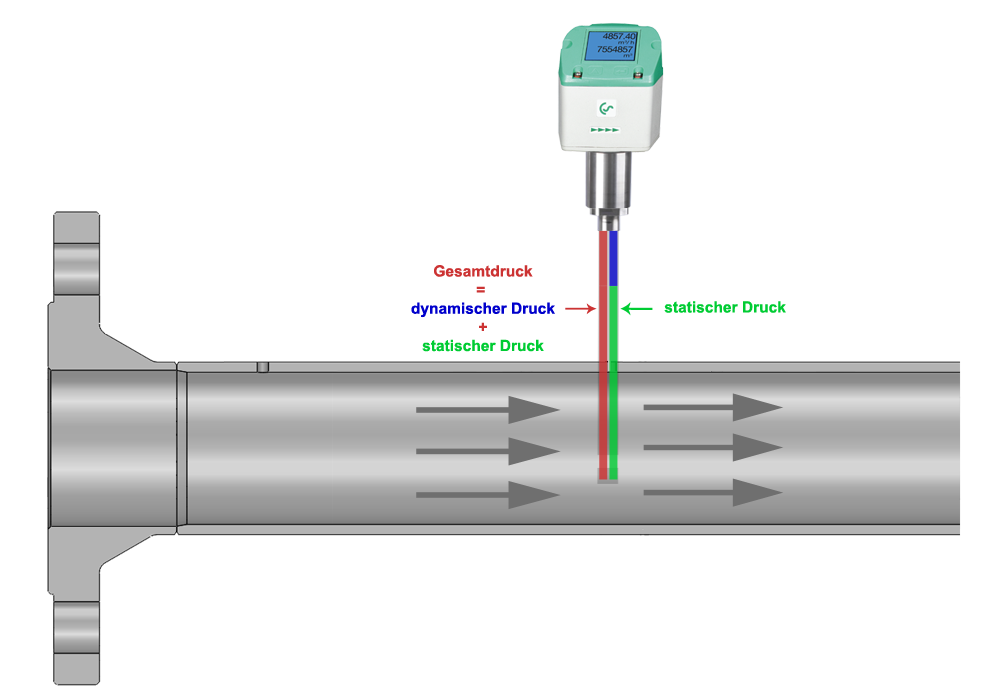

With our innovative VD 500 volumetric flow sensor, you can identify specific measures to significantly reduce the Energy consumption of your compressed air system. Positioned directly behind the Compressor, it precisely records the volume flow, Pressure and Temperature and enables the Efficiency measurement of individual Compressors. Compressors can be compared with each other during operation and it can be checked whether they actually achieve the delivery rate specified in the data sheet.

The specific power of a Compressor describes the amount of energy required to deliver a certain amount of air. It is calculated by dividing the active electrical energy consumed by the volume of air produced. With the precise measuring of the VD 500 and an active power meter, you can determine the specific power of your Compressed air Compressor in real time. Whether for a short-term audit over 7 days or as permanent monitoring: determining the specific power enables you to evaluate the efficiency of your system and detect any deterioration. Thanks to the integrated Display and various bus systems, you have an overview of all relevant Measured values and can react quickly and efficiently.

Thanks to its innovative piercing design, it can be installed under pressure during operation and the compressed air supply does not need to be shut off during installation. It is simply inserted and removed from the line using a standard ½" Ball valve. Its design is lightweight and compact, meaning that it can be installed by a single person without any additional tools.

Further advantages of the VD 500 from CS INSTRUMENTS include its unique sensitivity in the lower Measuring range. The measuring range start value of the sensor starts at 2 m/s and thus covers the entire operating range of speed-controlled compressors (VSD) and other compressors. It is also particularly suitable for very high Flow rates, up to 224 m/s and 600 m/s respectively.

Furthermore, the VD 500 is suitable for high Temperatures, up to 180°C there are no restrictions. The sensor is also protected against the aforementioned contamination thanks to its specific design.

In summary, the VD 500 from CS INSTRUMENTS is a turnkey solution for monitoring and checking the Efficiency of your Compressor. It helps with the Calculation of compressed air costs, reveals potential savings and helps to save money.