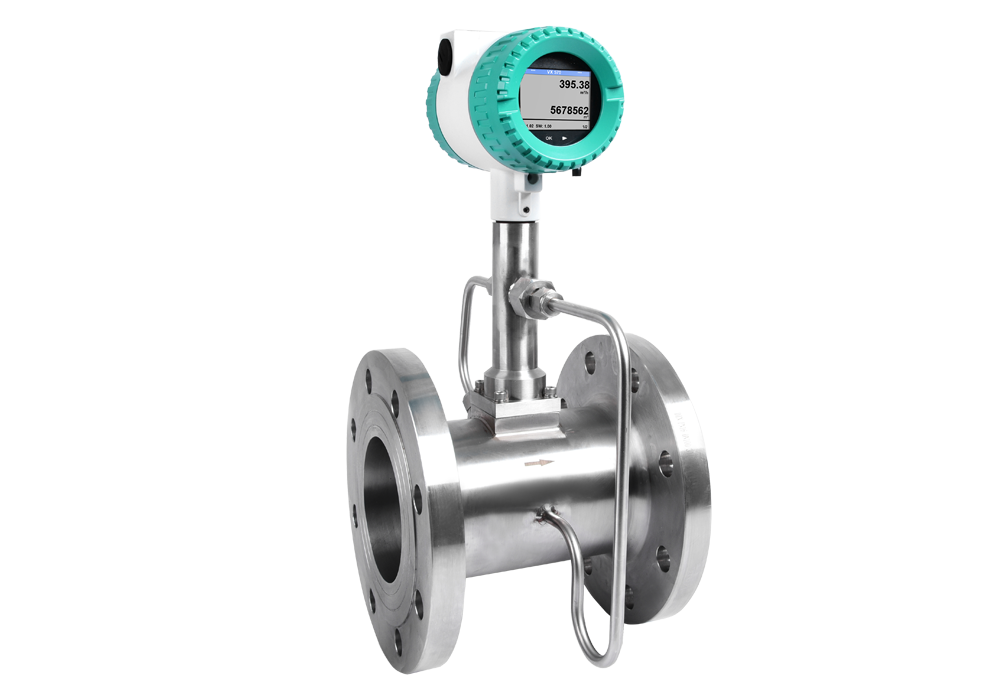

VX 570 - Vortex sensor for flow measurement

for technical gases, mixed gases - also with changing composition, steam and liquids

Industrial turbo compressors are Compressed air generators that are often used in industries such as the automotive industry, the iron and steel industry, glass production and the textile industry. Due to the high Energy consumption of turbo compressors, the operating costs are very high. This results in the need to continuously measure the flow of the Compressed air produced and monitor the Efficiency of the Compressors.

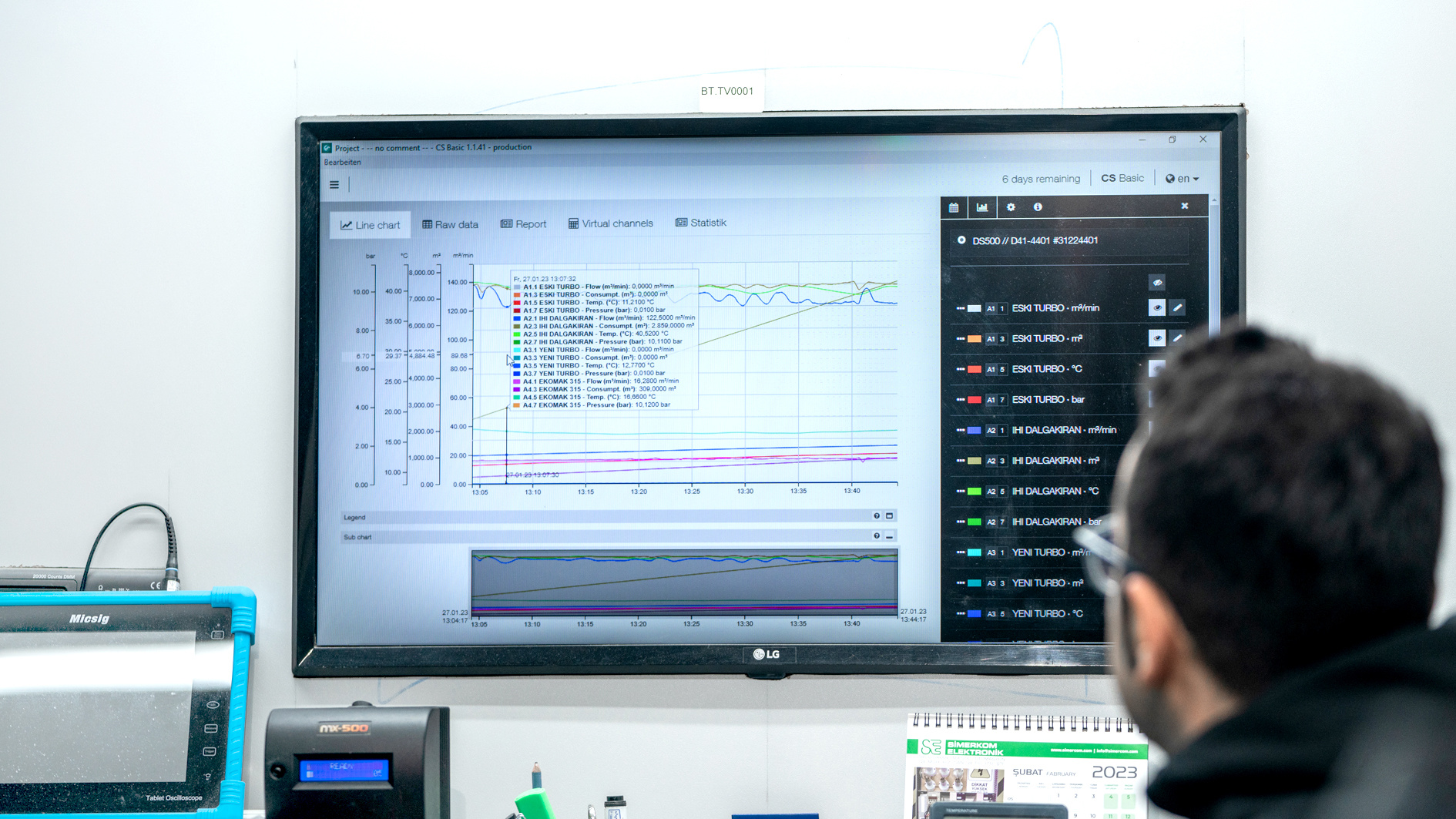

Thanks to Vortex flow meters, continuous monitoring of the compressed air flow of turbo compressors is very easy. Measuring, recording and visualising the data is handled by CS INSTRUMENTS systems.

The high-precision VX 570 Vortex flow meter from CS INSTRUMENTS provides you with the data you need to optimise your consumption and improve the system's sustainability figures. You can easily monitor the consumption of different fluids with just one VX 570 flow meter, and you can monitor this data in a computer environment thanks to the DS500 Chart recorder and CS INSTRUMENTS Basic Software, also offered by CS INSTRUMENTS.

To optimise the energy costs of the system, the turbocompressor must be operated with the greatest possible Efficiency. To achieve this efficiency, it is necessary to monitor and report the Compressor's flow rate. If a technical problem occurs with the flow rate, it should be quickly identified and rectified. This process can be easily tracked with the CS INSTRUMENTS VX 570 Flow sensor. For a very small investment, you can save thousands of euros in energy costs incurred each year due to Losses in the Efficiency of your Compressor.