OIL CHECK 500 Portable

The Portable version of our monitoring system is supplied directly in a practical case.

Contamination by oil can occur at several points during the preparation of compressed air. This poses a potential risk to machinery, the environment and health. The OIL CHECK 500 monitoring system continuously analyses the compressed air, detects even the smallest residual oil values and ensures that the air quality complies with applicable standards.

The OIL CHECK 500 impresses with its particularly easy handling and user-friendly operation, which makes it quick and effortless to use. Uniquely sensitive to gases of the recommended oil vapour standard according to ISO 8573-5.

Using the innovative "Forced Pressure Variation" validation process, the OIL CHECK 500 generates internal compression stages in the test gas to identify gradual increases in concentration, for example due to filter saturation. This method, which is protected by CS INSTRUMENTS, can be used to compensate for ageing or contamination-related components in the measurement signal, in particular long-term drifts. No wearing parts such as activated carbon filters are required to generate zero air. The result is low maintenance and long-term stable measuring.

The sensor unit can be replaced by the customer on site. This eliminates the need to return the entire device for recalibration.

All functions / components are monitored internally. A complete function test report can be printed out using the service software.

Compact measuring devices, easy handling and reduced logistics costs.

Continuous monitoring of residual oil content in compressed air and other gases.

The Portable version of our monitoring system is supplied directly in a practical case.

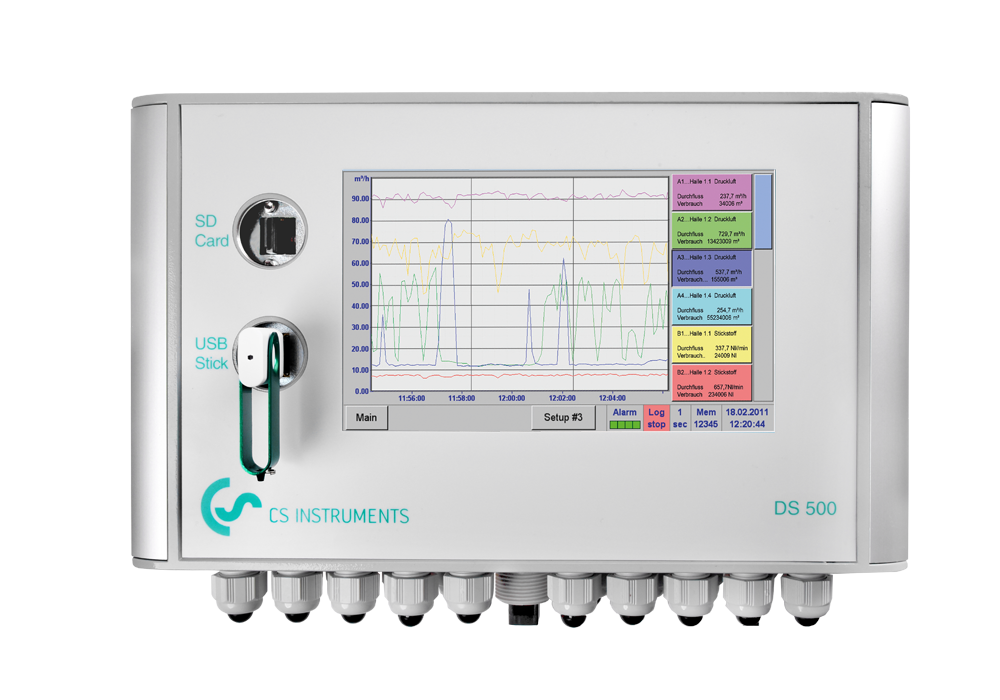

Up to 12 optional sensors can be connected. 7" colour screen with touch panel.

Data evaluation in graphic and table form - reading out of the measuered data via USB stick or Ethernet. License for two working places.